Your Reliable Cover Glass Designer & Manufacturer In China

Bunsun is devoted to customize the most perfect cover lens solution for your projects

What Cover Glass is for?

Capacitive touch panel is composed with touch sensor, bonding material and cover lens. Firstly, the main function of cover lens is to physically protect touch senor from damage. Secondly, cover lens is the topside layer of the whose module, its cosmetic design is the important part of the whole module’s appearance design.

Finally, when the touch panel is applied with stylus touch input, stylus writing on the cover lens will be required with like page-writing feeling.

Featured Cover Glass

Thickness: 0.4mm~3.0mm

Silk Colour: Black, White, Silver

Customized & Semi-Customized Supported

Structure: G+G, G+Film

Thickness: 0.4mm~3.0mm

Silk Colour: Black, White, Silver

Customized & Semi-Customized Supported

Structure: G+G, G+Film

Thickness: 0.4mm~3.0mm

Silk Colour: Black, White, Silver

Customized & Semi-Customized Supported

Structure: G+G, G+Film

Thickness: 0.4mm~3.0mm

Silk Colour: Black, White, Silver

Customized & Semi-Customized Supported

Structure: G+G, G+Film

Thickness: 0.4mm~3.0mm

Silk Colour: Black, White, Silver

Customized & Semi-Customized Supported

Structure: G+G, G+Film

Thickness: 0.4mm~3.0mm

Silk Colour: Black, White, Silver

Customized & Semi-Customized Supported

Structure: G+G, G+Film

Key Parameter for Industrial-grade Cover Glass

Min. 3 years product longevity since MP

Typical more than 10K test times

More than 2 weeks reliability test guarantee

Tolerable operating temperature up to -20~75C

Easy to Customize Cover Glass

Differ from sensor size being standard size matching with display size, cover lens could be individualized customize by combine-considering product function requirement and appearance design expectation.

Bunsun can customize cover lens with options of material, thickness, color, shape and surface treatment, and more.

Materials for Cover Glass

The material of cover lens could be strengthened glass, PMMA (Polymethyl methacrylate)/ PC or PET. while Bunsun just specialize in offering glass type cover lens, using

Corning Gorilla Glass : it is the most famous cover glass material, recognized of superior performance, durability and available being very thin or thick.

AGC(Asashi) Glass : it is high-end glass brand of Float glass manufacturing technology. It has series of green galss and clear white glass.

SG Aluminosilicate Glass: it is one of most well-known China brands. Its Aluminosilicate Glass is with advantage of high hardness>9H, and strong anti-impact capability.

Cover Glass Thickness

The recommended cover lens thickness is 0.55mm, 0.7mm, 1.1mm, 1.8mm, 2.0mm, 2.2mm, 3mm and 4mm.

The thickness choice is not only depending on impact protection, but also considering to match related controller IC ability. If the project requires a thicker cover glass, we will choose touch controllers like EETI, Ilitek, that could support cover glass thickness up to 15mm.

Free Shape of Cover Glass

The shape of cover glass could be free-customized to any shape, rectangle, trapezoid, circular even irregular shape, and adding hole, edging, precise machined by CNC machine.

Silk Screen of Cover Glass

Variety of color and printing layers, capable of diverse inks such as high-temperature ink, IR ink or metal ink variety of color and printing layers, capable of diverse inks such as high-temperature ink, IR ink or metal ink.

Surface Treatments for Cover Glass

AG(Anti-glare) : By creating single or double-side rough surface on the cover lens in order to avoid bright glaring visiual feeling, meanwhile strengthen anti-scratch performance.

AR(Anti-reflection): By coating a AR film on the cover lens to reduce the reflection on the cover glass surface, leading improved the transmittance rate of display through cover lens.

AF(Anti-finger): By vacuum coating a type of chemical material on the cover glass surface to prevent the cover glass surface from fingerprints, smudges and greasy dirt being left on, to keep surface clean.

Cover Galss in Wide Applications

Size: 3.5 inch

Strength Method: Chemically Strengthened Glass

Surface Treatment: AF

Color Silk: White

Size: 15 inch

Thickness: 2.0 mm

Strength Method: Chemically Strengthened Glass

Surface Treatment: AG on Single Surface

Size: 8.4 inch

Thickness: 2.0 mm

Strength Method: Chemically Strengthened Glass

Surface Treatment: AG on Single Surface

Size: 7.0 inch

Strength Method: Chemically Strengthened Glass

Surface Treatment: AG on Single Surface

Color Silk: White

Size: 15.0 inch

Strength Method: Chemically Strengthened Glass

Surface Treatment: AG on Single Surface

Color silk: White

Size: 30 inch

Thickness: 2.0 mm

Strength Method: Chemically Strengthened Glass

Surface Treatment: AG on Single Surface

Color Silk: Black Silking, Anti-UV 1300 Hrs

Related Product

Normally brightness of sunlight readability is suggested min 700cd/m2.

Below application suggestion for your reference.

The bonding material options including DST(double-side tape), OCA(Optical Clear Adhesive) and OCR/LOCA(Liquid Optical Clear Adhesive).

For the bonding between display and touch sensor, normally the priority option is air bonding by double-side tape if the customer does not have special requirement.

It is more difficult to do OCA bonding, because there is a front bezel on the TFT surface, that is not full flat surface. The yield rate is lower, the material cost is also much higher.

Besides, if do optical bonding for TN type TFT, it will cause water wave problem when pressing the cover surface. So we recommend OCA bonding only for IPS type TFT.

We guarantee 90% max. RH for Ta ≤40℃

<50%RH for 40℃<Ta≤Maximum operating temperature

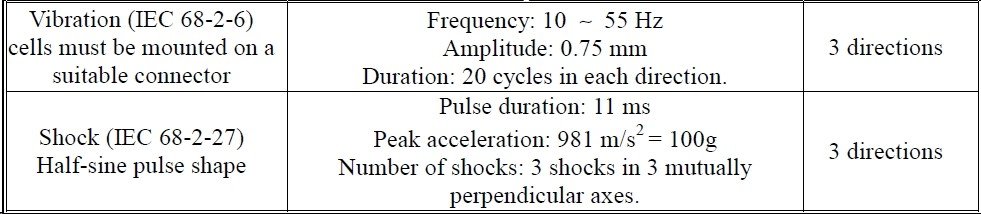

Below is the standard shock and vibration test condition for TFT product

We only select industry-grade TFT panels, that these leading manufacturers guarantee min. 3 years longevity from MP.

Bunsun guarantee available supply as long as panel is not EOL.